Introduction

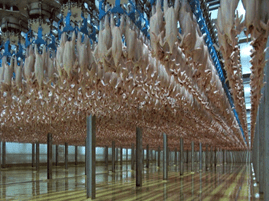

To prevent or even to reduce the deterioration process, particularly microorganism development, but also reduces weight loss and discoloration of the surface owing to hemoglobin oxidation. Different systems of primary chilling are in use (including immersion in iced water, especially for poultry) but air chilling is the most common. Chilling has to be carried out quickly after carcass dousing at the end of the slaughter until the meat is processed for consumption. Definition

Definition

Preservation method in which raw or processed food is cooled to a temperature between zero degree and five degree Celsius (0°C-5°C). Chilling retards spoilage and prevents food poisoning by slowing the growth of microbes (present in all food) during storage.

Shelf life:

Type of meat Expected storage life at – 1°C

Beef up to 3 weeks

Veal 1–3 weeks

Lamb 10–15 days

Edible offal 7 days

Rabbit 5 days

Procedure:

Factors

A. Low air temperature

• Not below -1°C

• -1°C freeze the meat surface

• -1°C impair its appearance

B. High air speed

• Range 0.75 to 1.5 m/s

• Greater speed higher weight loss

• Greater operational cost

C. High relative humidity

• Range 90 to 95 %

• Higher humidity lower weight loss

• Difficult to control

D. High refrigerating capacity

• Improved meat and fat color

• Improved shelf life

• Reduced weight loss

• Reduced drip

Classification

A. Primary chilling

• Completed when the warmest point of the carcass has reached a temperature of about 7°C (3°C for edible offal).

• Basically in this carcass dip in cold water where temperature reached 7°C to slow microbial proliferation.

• These temperatures can be arrived at in 16–24 hours in small carcasses and in less than 48 hours in large carcasses (Centre of the hind leg).

B. Quick chilling

• Can used in small chambers or in cooling tunnels

• Completed in 3 phases

i. During the first phase the air temperature is maintained at about 0°C, carefully controlling the risk of superficial freezing while air movement is maintained at a high level.

ii. For large carcasses, after 10–12 hours the air circulation inside the store is reduced, maintaining temperature and humidity conditions; this second phase lasts another six to 10 hours.

iii. After this period the meat is transferred to cold storage chambers where the carcass temperature is stabilized, concluding the third phase.

Problems

• Cold shortening can often be seen in beef and mutton, when the meat, still in its pre-rigor phase, reaches temperatures of 10°C or lower. These conditions cause irreversible contractions of the muscle tissue which toughen the meat even after prolonged ripening.

• Increase in investment and higher operational costs

• The chilling period can be reduced by lowering the air temperature (surface freezing risks) or increasing air speed (higher operational costs) or both.

How cold shortening can be prevented?

• By electric stimulation method.

Chilled Meat Storage

• To serve as buffer stock between production and shipment and/or consumption.

• During storage, ageing (ripening) of the meat also occurs.

• Ageing depends on temperature and can be accelerated by increasing it, but for hygienic reasons it is recommended that 4°C be used with a relative humidity of 85–95 percent. Because during this period moisture absorb and meat will become soft and tender.

• In these conditions ageing takes place in a few hours for poultry, two to four days for pork, four days for mutton and two weeks for beef. It can thus be considered as complementary treatment only for the last two products.

• When chilled meat is stored for long periods a lower temperature without the risk of freezing should be used; normally 0°C is a reasonable choice.

Chemical and Physical Properties of Meat

What is Curing of Meat and Meat Curing Methods

Smoking of Meat and Smoking of Meat Process

What is Canning of Meat and Process of Canning Meat

Preservation of Meat by Salting

References

- www.fao.org/docrep/004/T0098E/T0098E02.htm

- https://www.businessdictionary.com/definition/chilling.htm